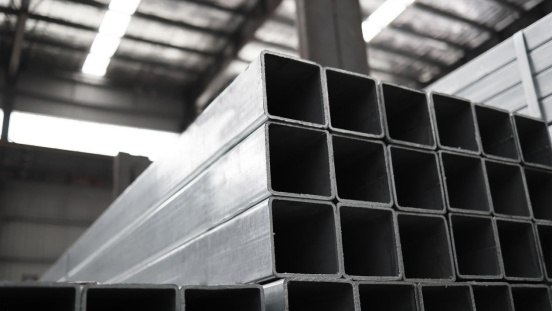

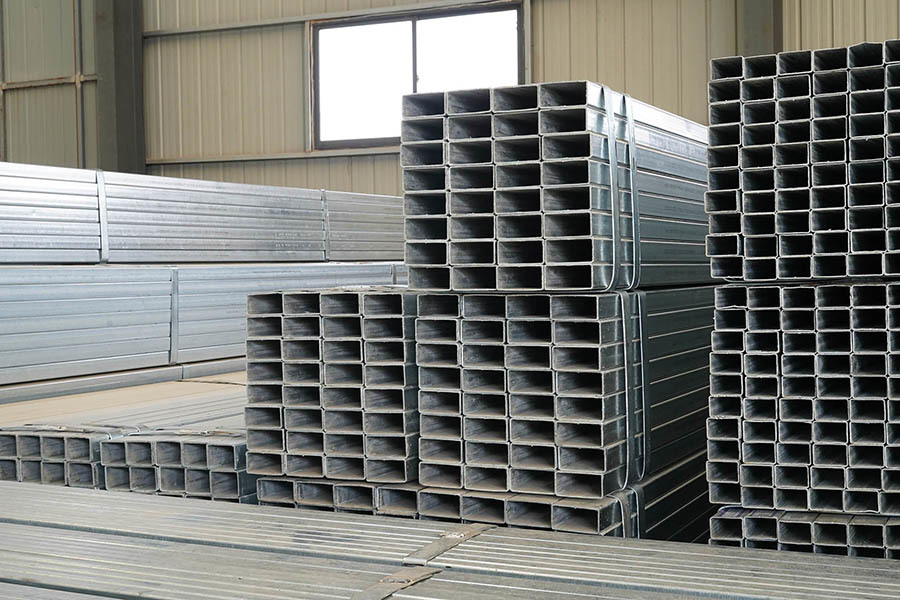

- Commodity name: Hot-dip galvanized square tube

Hot-dip galvanized square tube

keyword:

Hot-dip galvanized rectangular tube

Products Detail

Hot-dip galvanized rectangular tube is a special process of steel pipe products, the production process involves the rectangular tube immersed in molten zinc, so that zinc and steel surface chemical reaction, so as to form a layer of dense zinc layer on the surface of the steel pipe.

Pretreatment: The steel pipe first needs to be pickled to remove iron oxide and other impurities on the surface. Then, further cleaning was carried out by a mixed aqueous solution of ammonium chloride and zinc chloride to ensure that the surface of the steel pipe was clean and free of stains.

Hot-dip plating: The pretreated steel pipe is fed into a hot-dip plating tank, which contains molten zinc. The steel pipe is immersed in the zinc liquid for a period of time, so that the zinc and the steel surface fully react to form a zinc-iron alloy layer.

Cooling and post-treatment: The galvanized steel pipe is taken out of the zinc liquid and cooled. As needed, other post-treatment steps such as cleaning, passivation, etc. may be performed to improve the corrosion resistance and surface quality of the steel pipe.

Strong corrosion resistance: The zinc layer on the surface of the hot-dip galvanized rectangular tube can effectively prevent the corrosion of the steel by the environment such as oxygen, acid and alkali, and salt spray, thereby prolonging the service life of the product.

Uniform coating: Through the hot-dip coating process, a uniform zinc layer can be formed on the surface of the rectangular tube to ensure that the corrosion resistance of the entire steel pipe is consistent.

Strong adhesion: The zinc layer and the steel surface form a close bond through a chemical reaction, with strong adhesion and not easy to peel off.

Good processing performance: hot dip galvanized rectangular tube has good mechanical properties and processing performance, can be cold punching, rolling, drawing, bending and other forming without damaging the coating.

Specification parameters

| SIZE mm | WEIGHT kg/m | |

| EST. LBS. PER FT. | ||

| 150 x 100 x 6.30 | 22.400 | 15.08 |

| 150 x 100 x 8.00 | 27.700 | 18.64 |

| 150 x 100 x 10.00 | 35.714 | 24.04 |

| 160 x 80 x 3.20 | 11.500 | 7.74 |

| 160 x 80 x 4.00 | 14.300 | 9.62 |

APPLICATION FIELD

FAQ

We are here to help you

* Note: Leave your contact information to get a free product quote

English

English