- Commodity name: ASTM A53 ERW Steel Pipe

ASTM A53 ERW Steel Pipe

keyword:

quality 800mm SSAW steel pipe for sewage

china hot dip zinc steel pipe/tube

Products Detail

ERW Steel Pipe Steel Iron Welded Tube ASTM A53

ERW welded steel pipe stands for Electric Resistance Welded welded steel pipe, a type of steel pipe that is manufactured using the ERW process.

ERW Tube Steel Grade:

| ASTM A53, ASTM A500, ASTM A795, API 5L | BS1387, BS1139, EN39, EN10219, EN10255 | JIS G3444 | GB/T3091, GB/T13793 |

| Grade A | S195 | STK290 | Q195 |

| Grade B | S235 | STK400 | Q235/Q235B |

| Grade C | S355 | STK500 | Q355 |

ERW Tube Specifications:

| ERW Tube Outside Diameter | ERW Tube Wall Thickness | ||||||

| SCH10 | SCH40 | Class A light | Class B medium | Class C heavy | |||

| DN15 | ½'' | 21.3mm | 2.11mm | 2.77mm | 2mm | 2.6mm | |

| DN20 | ¾'' | 26.7mm | 2.11mm | 2.87mm | 2.3mm | 2.6mm | 3.2mm |

| DN25 | 1'' | 33.4mm | 2.77mm | 3.38mm | 2.6mm | 3.2mm | 4mm |

| DN32 | 1¼'' | 42.2mm | 2.77mm | 3.56mm | 2.6mm | 3.2mm | 4mm |

| DN40 | 1½'' | 48.3mm | 2.77mm | 3.68mm | 2.9mm | 3.2mm | 4mm |

| DN50 | 2'' | 60.3mm | 2.77mm | 3.91mm | 2.9mm | 3.6mm | 4.5mm |

| DN65 | 2½'' | 73mm 76mm | 3.05mm | 5.16mm | 3.2mm | 3.6mm | 4.5mm |

| DN80 | 3'' | 88.9mm | 3.05mm | 5.49mm | 3.2mm | 4mm | 5mm |

| DN90 | 3½'' | 101.6mm | 3.05mm | 5.74mm | |||

| DN100 | 4'' | 114.3mm | 3.05mm | 6.02mm | 3.6mm | 4.5mm | 5.4mm |

| DN125 | 5'' | 141.3mm | 3.4mm | 6.55mm | 5mm | 5.4mm | |

| DN150 | 6'' | 168.3mm 165mm | 3.4mm | 7.11mm | 5mm | 5.4mm | |

| DN200 | 8'' | 219mm | 3.76mm | 8.18mm | |||

| DN250 | 10'' | 273.1mm | 4.19mm | 9.27mm | |||

ERW Tube Application:

ERW welded carbon steel pipes widely used across industries due to it's strength,cost-effectiveness,and adaptabillity

Circulation Field: Water delivery steel pipe,Oil and Natural Gas Delivery Steel Pipe .Agricultural irrigation steel pipe, Drainage steel pipe.

Structure Field: Construction scaffold,Steel Structure,Agriculture GreenHouse Structure,Solar Tracker Structure, Fence post, Sport equipment, Light pole, Equipment manufacturing.

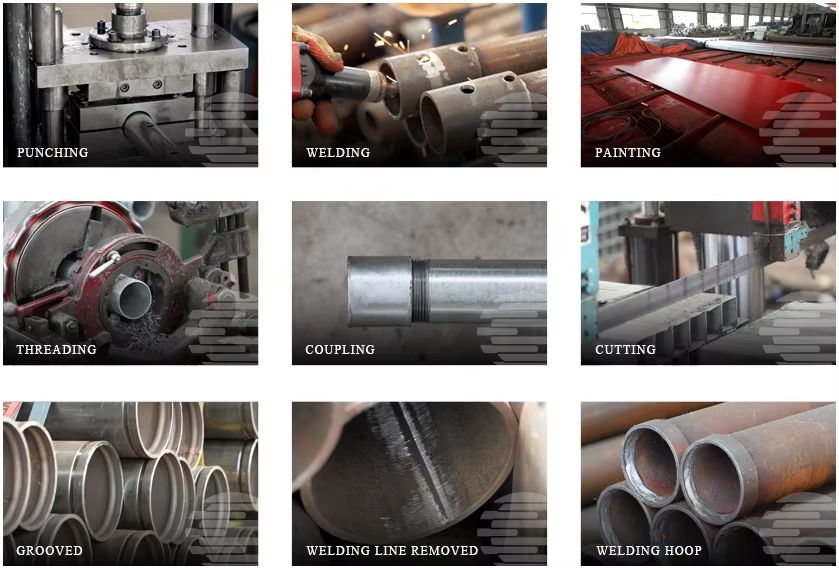

ERW Welded Steel Pipe Factories and Processing:

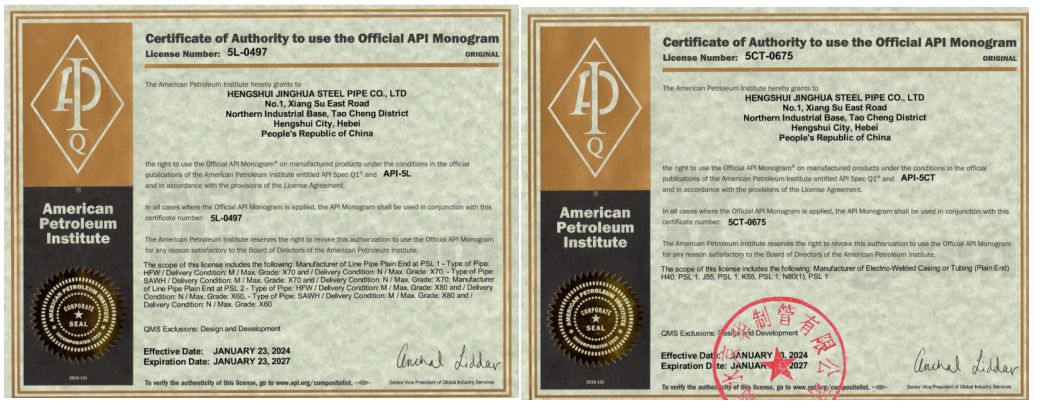

Our Certificater:

ERW steel pipe, which stands for Electric Resistance Welded steel pipe, is a high-quality welded tube manufactured through a precise process that forms steel coils into a cylindrical shape and uses electric resistance to create a strong, consistent seam. This type of pipe is widely recognized for its excellent strength, uniformity, and cost-effectiveness, making it a preferred choice across numerous industrial, structural, and fluid transportation applications.

Available in a wide range of sizes, wall thicknesses, and material grades, ERW steel pipes comply with international standards such as ASTM A53, ASTM A500, API 5L, BS 1387, EN 10219, JIS G3444, and GB/T 3091. Common grades include Grade A, Grade B, S235, Q235B, and STK400, among others, ensuring suitability for various environmental and mechanical requirements.

These pipes are produced in outside diameters ranging from DN15 (½ inch) to DN250 (10 inches) and beyond, with wall thicknesses categorized as light, medium, and heavy classes—e.g., SCH10, SCH40—to meet different pressure and structural demands. The ERW manufacturing process ensures a smooth inner and outer surface, improved dimensional accuracy, and reliable weld integrity without the use of filler materials.

ERW steel pipes are extensively used in water supply systems, oil and gas transportation, agricultural irrigation, scaffolding, structural frameworks, fencing, greenhouse construction, solar support structures, and machinery manufacturing. Their adaptability, ease of fabrication, and balanced performance between durability and affordability make them ideal for both light-duty and heavy-duty applications.

Whether applied in construction, infrastructure, or industrial projects, ERW steel pipe offers consistent quality, excellent weldability, and long-term service life, serving as a fundamental component in modern engineering and building industries.

APPLICATION FIELD

FAQ

We are here to help you

* Note: Leave your contact information to get a free product quote